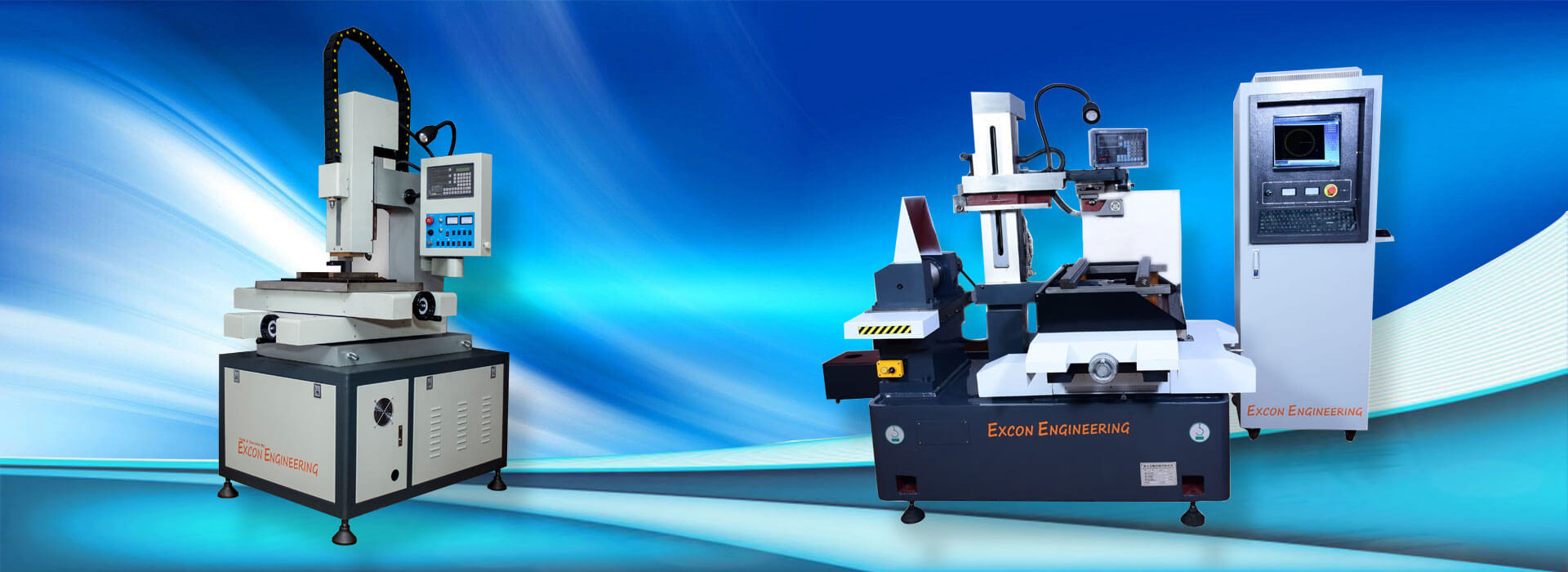

EDM drilling machine

Due to our proficiency of this field, we are engaged in presenting Small Hole EDM Drilling Machine. We are presenting these products to customers within given time-frame.

We Are Authorized Deals and Distributors

of Vinpack Machines For Karnataka

Excon Engineering in Bangalore boasts of a highly modern and state-of-the-art facility. They strictly adhere to the industrial quality guidelines to offer the customers the best satisfaction and happiness. It is their trustworthy service for which people come back to them whenever there is a requirement.

They always ensure to inform the customers from beforehand about the approximate cost for the specific service to avoid any confusion later on. They can be counted on because of their extensive experience. In order to talk to one of their crew members, one can use the above-mentioned phone numbers.

Due to our proficiency of this field, we are engaged in presenting Small Hole EDM Drilling Machine. We are presenting these products to customers within given time-frame.

Outfitted with all the advanced High Speed CNC wire EDM, technology and machinery, we are instrumental in providing a broad collection of CNC Wire Cut EDM.

We have carved a niche for ourselves, in offering a wide assortment of Used Mitsubishi CNC Wire Cut. Easy to operate, CNC wire cut machines offered by us are extremely durable.

| Specification | Unit | DX7725 | DK7735 | DK7745 | DK7750 | DK7763 |

|---|---|---|---|---|---|---|

| Work Table Travel(X and Y) | mm | 250*320 | 350*450 | 450*550 | 500*800 | 630*1000 |

| Work Table Dimension | mm | 500*320 | 740*520 | 840*620 | 1145*650 | 1380*800 |

| Max Job Load Capacity | KG | 250 | 350 | 450 | 800 | 1000 |

| Machine Weight | KG | 800 | 1400 | 1700 | 2000 | 2300 |

| Max Job Cutting Thickness | mm | 250 | 600 | 600 | 600 | 600 |

| Max Cutting Taper | mm | +/- 3 degree for 80mm | +/- 6 degree for 80mm | |||

| Cutting speed | Sqr, mm/ min | 100 | ||||

| Power consumption | KVA | 1.5 | ||||

| Electrode wire dimension | mm | 0.18 | ||||

| Surface | RA | Max 2.5 Ra in single cut & in multipass 1.8 to 1.2 | ||||

Please Fill The Form :